We specialize in the research, development, and manufacturing of industry-leading Hollow Rotary Actuator technology, engineered for unparalleled accuracy and reliability.

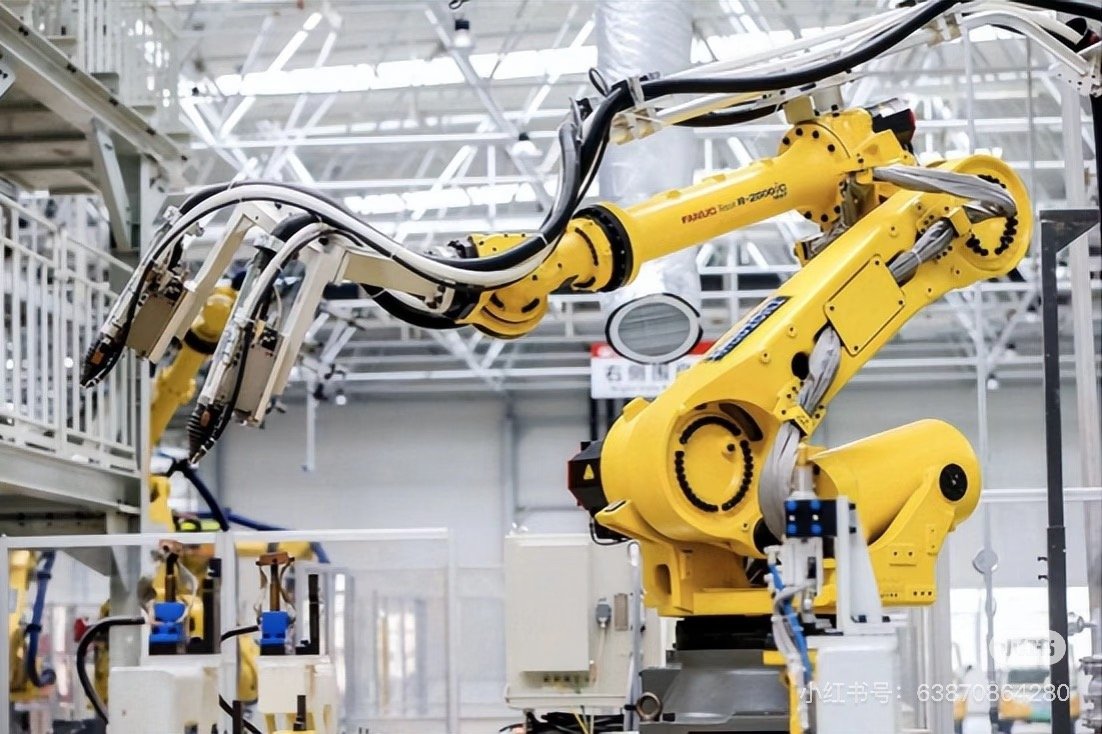

Our components form the core of modern industrial automation systems, providing the critical performance needed for complex robotics, advanced manufacturing, and innovative mechatronics.

Discover robust motion control solutions designed to elevate your project's potential.

High-Precision Hollow Rotary Actuators & Motion Control Systems

Our Core Product Categories

High-Performance Motion Control Products

GSFD Low Voltage Servo Drives

GSHD Low Voltage Servo Drives

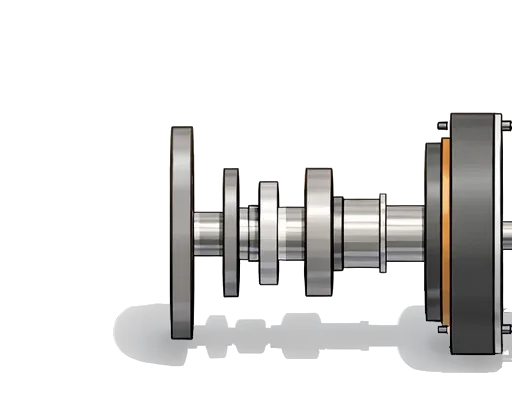

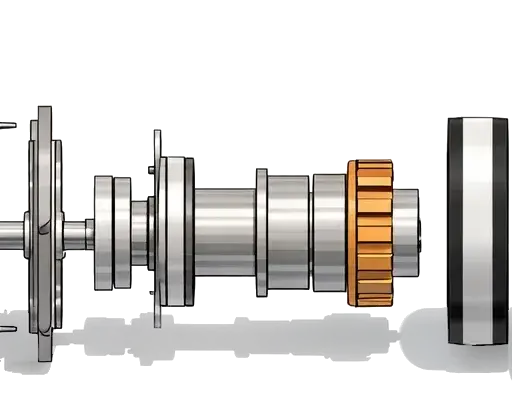

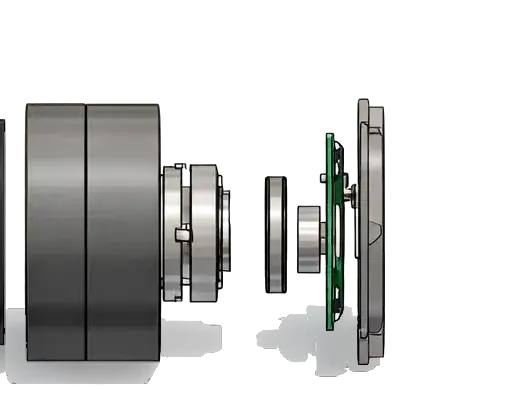

HAMF Hollow Shaft Rotary Actuator With Enlarged Bore

HAS Medium Solid Rotary Actuator

HAT Hollow Rotary Actuator

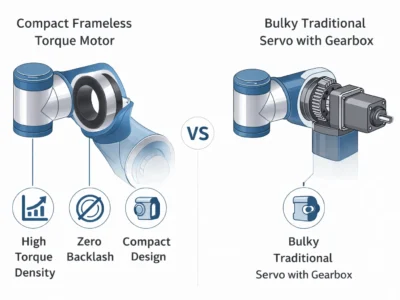

HBM Frameless Torque Motor

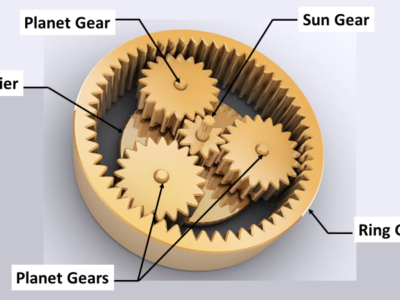

HPG High-Precision Planetary Rotary Actuator

USERVO-FLEX Communication Drives

Solutions

Solutions for Your Industry

From semiconductor manufacturing and 3C automation to advanced medical equipment, our products provide the critical precision needed to push the boundaries of technology. We are committed to empowering our clients by helping them reduce operational costs, accelerate product development cycles, and enhance their competitive edge in the global market.

Humanoid Robots

Collaborative Robots

NC Machine Tools

Laser Equipment

3C Automation

Medical Equipment

Semiconductor Equipment

Non standard automation

Our Core Strengths

ABOUT HOBBER INTELLIGENT

Our strength is built on a foundation of excellence. The core Hobber team brings over 20 years of focused expertise in the precision transmission field, supported by our affiliate enterprises—top-tier domestic leaders in harmonic and planetary reducers. By combining these mechanical advantages with advanced mechatronics, we provide highly integrated joint modules that enable customers to achieve rapid product implementation, significantly reduce operating costs, and improve their competitive advantage.

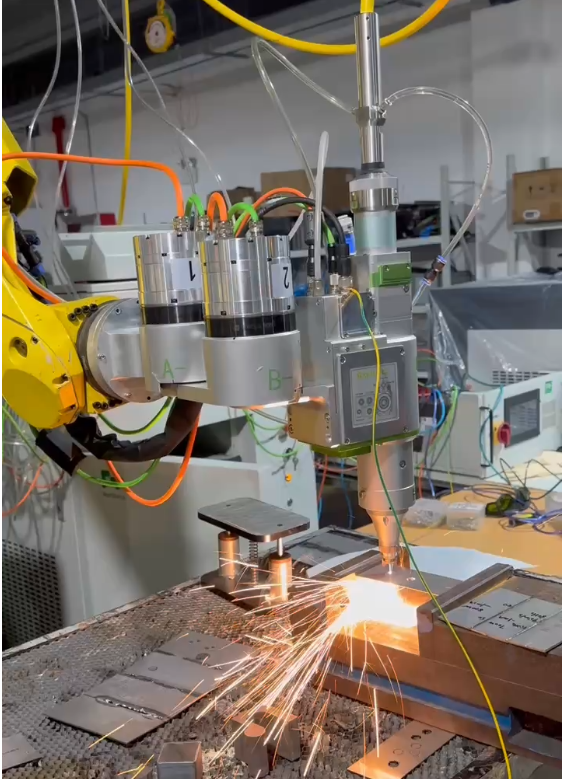

Robotic Joint Module for High-Precision Laser Cutting

Challenge: An advanced manufacturing client required an ultra-precise motion system to create complex micro-holes on 3D curved surfaces. Their traditional machinery lacked the necessary compactness and positioning accuracy for the task.

-

✔

Solution: The client adopted the Hobber™ Robotic Joint Module Series, selected for its exceptional rigidity, absolute positioning accuracy, and smooth, low-vibration motion profile.

-

✔

Implementation: A compact "wrist" assembly was built using two HOBBER™ High-Torque Modules. This enabled the laser head to maintain perfect perpendicularity and a constant focal distance, achieving flawless cutting on complex workpiece surfaces.

Authority & Presence

Exhibitions & Events

Exhibition Scene 01

Exhibition Scene 02

Exhibition Scene 03

Exhibition Scene 05

Exhibition Scene 06

Exhibition Scene 07

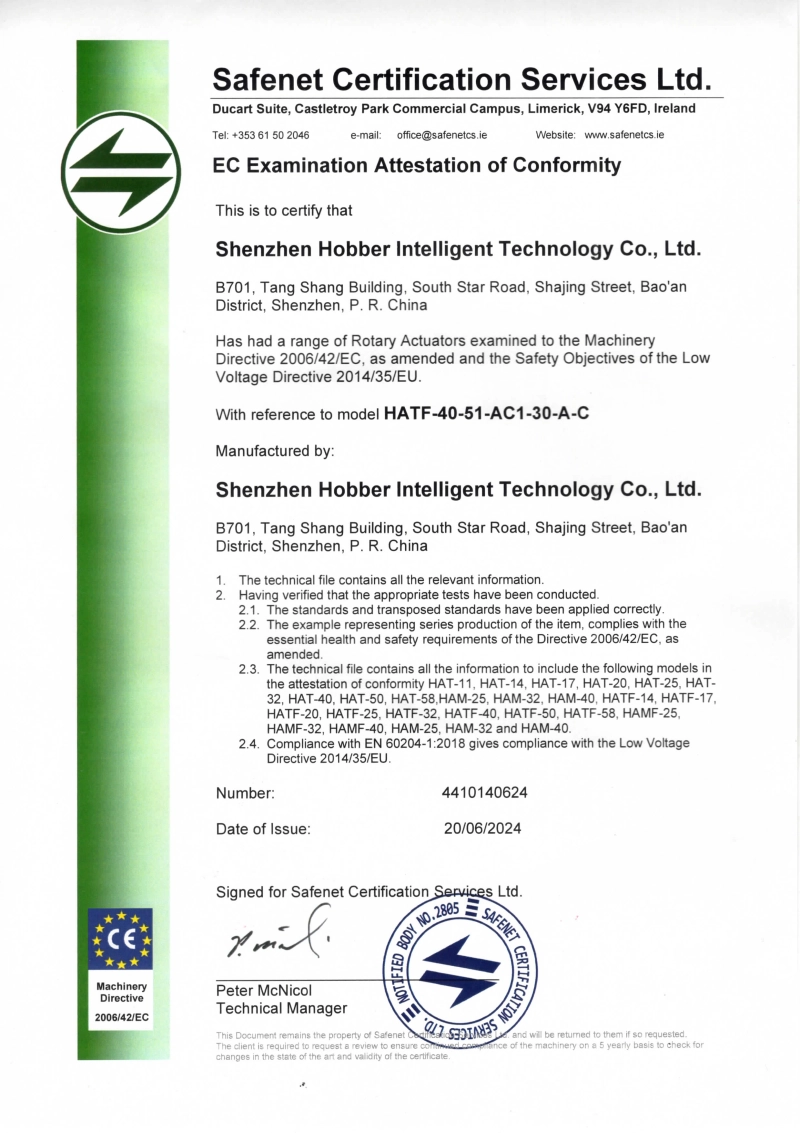

CE Certification

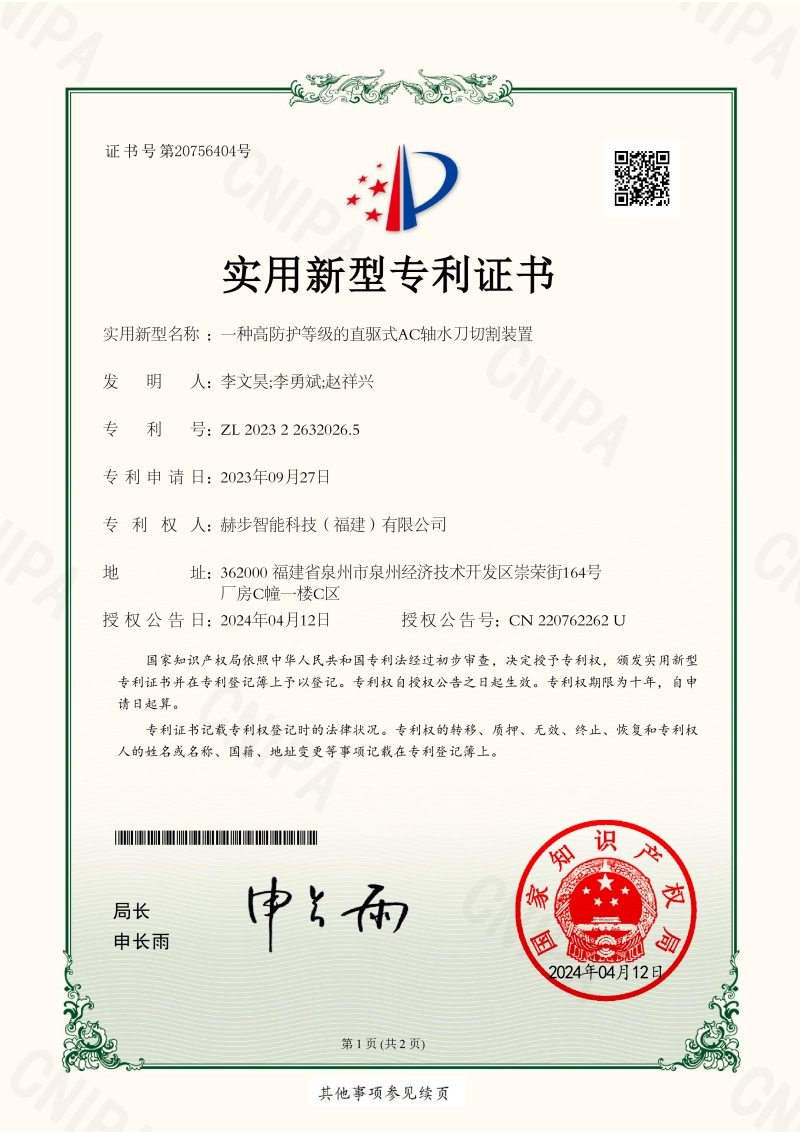

Invention Patent

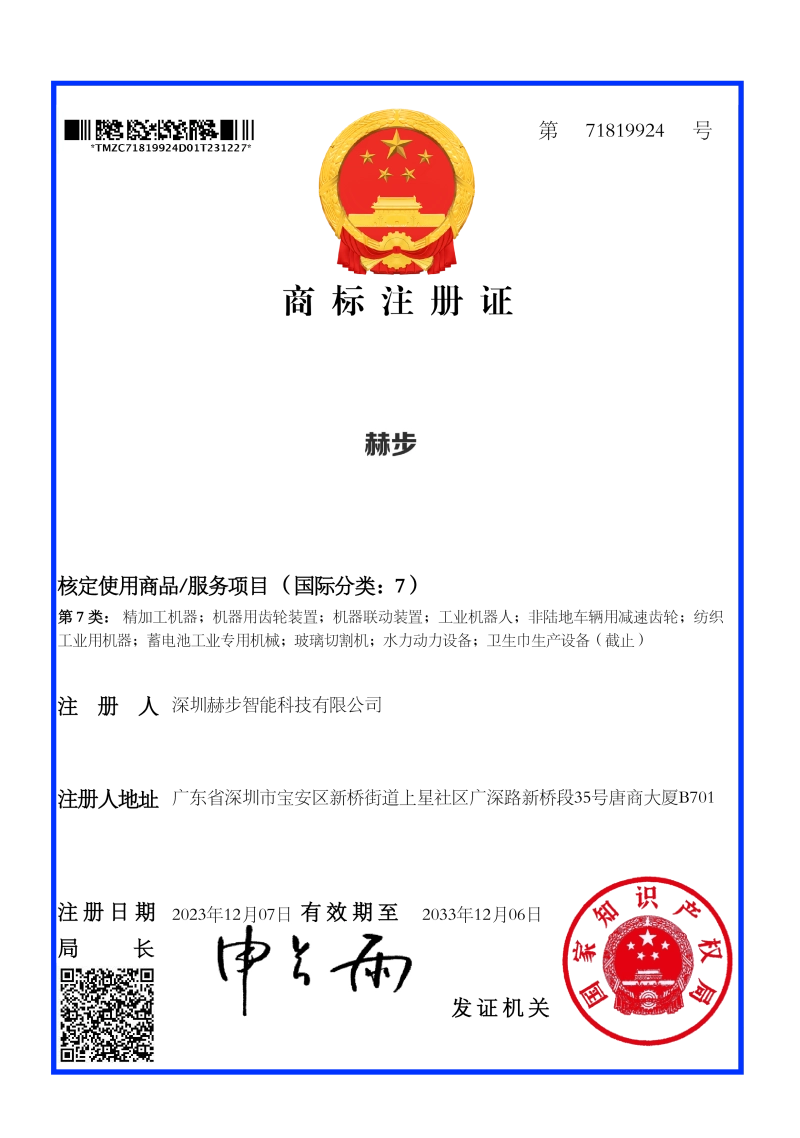

Registered Trademark

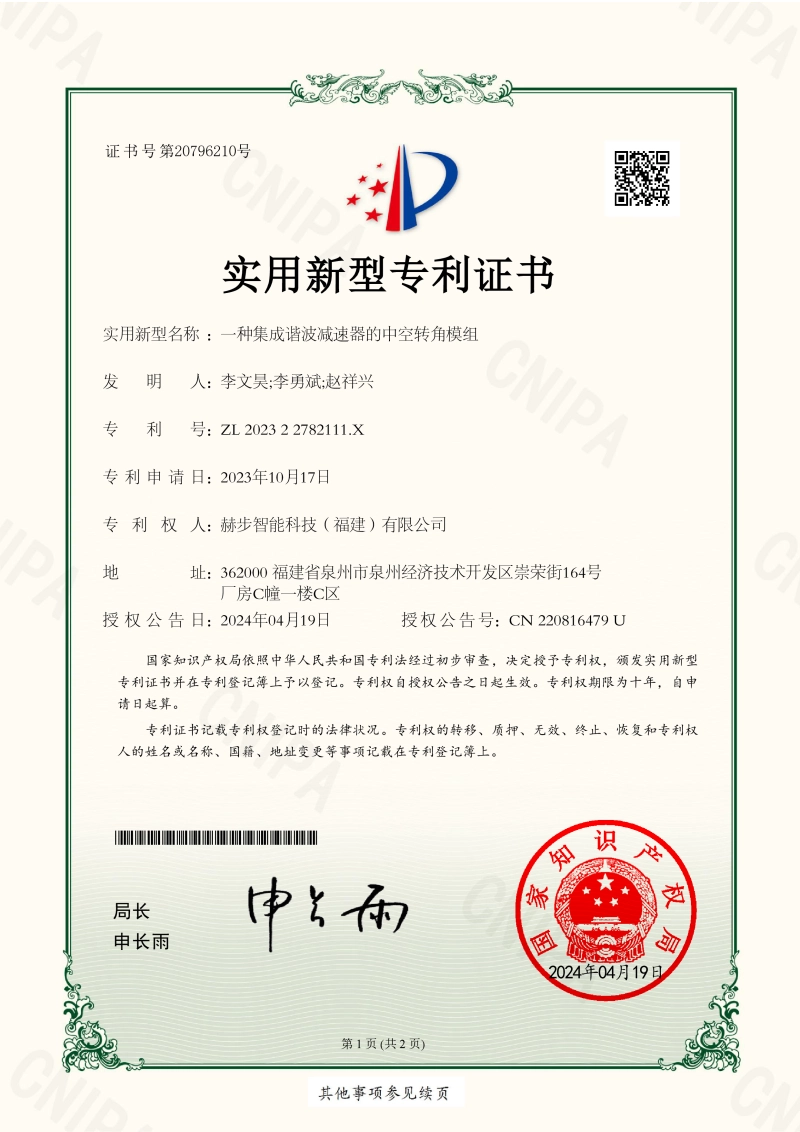

Integrated Reducer

Waterjet Head Patent

Low-vibration Module

Hollow Shaft Patent

Precision Drive Module

News & Technical Insights

OUR LOCATIONS

SHENZHEN HEADQUARTERS

Mon – Fri: 9:00am – 6:00pm (GMT+8)